What is Silicon Carbide

Silicon carbide, an inorganic substance with the chemical formula SiC, is made from quartz sand, petroleum coke (or coal coke), wood chips (salt is added to produce green silicon carbide), and other raw materials smelted at high temperatures in resistance furnaces. Silicon carbide also exists in nature as a rare mineral, moissanite. In C, N, B and other non-oxide high technology refractory raw materials, silicon carbide for the most widely used, the most economical one, can be called gold steel sand or refractory sand. Chinese industrial production of silicon carbide is divided into two kinds of black silicon carbide and green silicon carbide, both hexagonal crystals, specific gravity of 3.20 to 3.25.

Silicon carbide and aluminum oxide are two of the most widely used abrasive materials. Both materials are available in a variety of shapes and sizes, and they can be used for a variety of applications.

Black SiC is suitable for working on cast iron, non-ferrous metal, rock, leather, rubber, etc. It is also broadly used as refractory material and metallurgical additive.

Black Silicon Carbide Macro Grits

Black Silicon Carbide Micro Powder

Green SiC is suitable for processing hard alloy, metallic and non-metallic materials with hard and brittle features such as copper, brass, aluminum, magnesium, jewel, optical glass, ceramics, etc. Super powder of it is also a kind of ceramic material.

Green Silicon Carbide Macro Grits

Green Silicon Carbide Micro Powder

Main Products Type

Parameter

| Description of items | Black Silicon Carbide | ||

| SiC | 90%-99% | ||

| Fe₂O₃ | 0.1%-0.35% | ||

| F.C | 0.1%-0.35% | ||

| Melting point (℃) | 2250 | ||

| Maximum service temperature (℃) | 1900 | ||

| Specific Gravity | 3.90g/cm³ | ||

| Mohs Hardness | 9.2 | ||

Production Sizes | Macro Grits | P | P12 P16 P20 P22 P24 P30 P36 P40 P46 P54 P60 P70 P8O P90 P100 P120 P150 P180 P220 |

| F | F12 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 | ||

| Powder | P | P240 P280 P320 P360 P400 P500 P600 P800 P1000 P1200 | |

| F | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 | ||

| JIS | #240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000 #2500 #3000 | ||

| Description of items | Green Silicon Carbide | ||

| SiC | 97.5%-99.5% | ||

| Fe₂O₃ | 0.05%-0.25% | ||

| F.C | 0.05%-0.25% | ||

| Melting point (℃) | 2250 | ||

| Maximum service temperature (℃) | 1900 | ||

| Specific Gravity | 3.90g/cm³ | ||

| Mohs Hardness | 9.4 | ||

Production Sizes | Micro Grits | ||

| FEPA | F12 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 | ||

| Micro Powder | JIS | #240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000 #2500 #3000 | |

| FEPA | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 | ||

Applications

Originally used as an abrasive material, Henan Superior Abrasives Silicon Carbide has since found applications in a variety of industries, including semiconductors.

- Abrasives

- Sintered Parts

- Furnace Burden

- Rust Removal

- Metal Matrix Composites

- High Temp Sensors

- Wire-saw

- Body Armor

- Vehicle Armor

- Milling

- Lapping

- Ceramic Wear Parts

- Blasting

- Brake linings

- Surface Treatment

- Refractory, Grinding

Packaging & Shipping

We can offer 1MT/25Kg Woven plastic bags, and 25Kg Paper bags.

Our Silicon Carbide is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

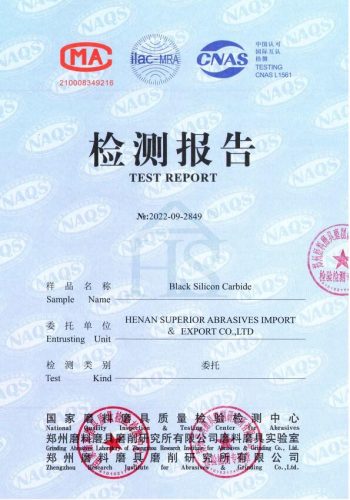

Quality Management Process

FAQ

We are manufacture. We began to produce silicon carbide material since 2001.

Expect metallurgical black silicon carbide, the silicon carbide from us are all of A grade quality.

We will check the chemical content, cleanness of the SiC grain and powder. And inspect the gradation, bulk density of SiC grain and powder.

Yes, we are open to get third part quality test before delivery.

No. We only produce A grade silicon carbide produced from high quality melted SiC blocks.

Yes, we provide free samples within 1 kgs. Customer only need to bear the logistic cost.

Yes, it need to provide export license to Chinese customs. We could provide it and make customs clearance in China.

It depends on the quantity required. Generally 5-10 days for FCL(20-25MT).

Our capacity is 1800-2000MT per month, annually appr. 22000 MT.High

Service

True high-quality product lies in details, our well-equipped lab&professional technicians can not only provide high quality and services for normal projects but also custom solutions for complex needs.

Custom Sizing

HSA can customize grain size & shape you need.

Custom Chemistries

HSA can customize chemistry you desired for your project.

Packaging

HSA offers a variety of packaging standards. We can also customize packaging ways for use or redistribution purposes.

Laboratory Testing

HSA has its own laboratory to provide analysis on material properties and characterization to meet your requirements.

Free Samples

We can provide free samples as long as you pay for shipping.

Particle Size Analysis & Chemical Analysis

We can analyze Chemistry, Particle Sizing, Particle Shape, Bulk Density, Specific Surface Area, Magnetics, Crushing Strength, and more.

Contact Us

Get a Quote

Email Address

sales@superior-abrasives.com

+86-18638638803

Address

No.68 Zhengtong Road, Zhengzhou, Henan, China