Grøn siliciumcarbidmikropulver

Green Silicon Carbide Micro Powder refers to the fine silicon carbide micro powder that uses JZFZ equipment to perform ultra-fine grinding and classification. Silicon carbide fine powder is mainly F240- F2000, because silicon carbide fine powder is mainly used in the abrasive industry, so there are special requirements for the classification of fine powder, there can be no large particles in the fine powder, so in order to reach the international and domestic product requirements, the general production is using JZF classification equipment for high precision classification.

Introduction

Green Silicon Carbide Micro Powder refers to the fine silicon carbide micro powder that uses JZFZ equipment to perform ultra-fine grinding and classification. Silicon carbide fine powder is mainly F240- F2000, because silicon carbide fine powder is mainly used in the abrasive industry, so there are special requirements for the classification of fine powder, there can be no large particles in the fine powder, so in order to reach the international and domestic product requirements, the general production is using JZF classification equipment for high precision classification.

Parameter

| Grit | Chemical Composition (%) | Size Distribution (%) | Bulk Density | ||||||||||||

| Sic | Fe2O3 | F.C. | D3 | D50 | D94 | ||||||||||

| F240 | ≥99 | ≤0.15 | ≤0.15 | ≤70 | 44.5±2.0 | ≥28 | 1.38 | ||||||||

| F280 | ≥99 | ≤0.15 | ≤0.15 | ≤59 | 36.5±1.5 | ≥22 | 1.31 | ||||||||

| F320 | ≥99 | ≤0.15 | ≤0.15 | ≤49 | 29.2±1.5 | ≥16.5 | 1.28 | ||||||||

| F360 | ≥99 | ≤0.15 | ≤0.15 | ≤40 | 22.8±1.5 | ≥12 | 1.26 | ||||||||

| F400 | ≥99 | ≤0.15 | ≤0.15 | ≤32 | 17.3±1.0 | ≥8 | 1.16 | ||||||||

| F500 | ≥99 | ≤0.15 | ≤0.15 | ≤25 | 12.8±1.0 | ≥5 | 0.98 | ||||||||

| F600 | ≥99 | ≤0.15 | ≤0.15 | ≤19 | 9.3±1.0 | ≥3 | / | ||||||||

| F800 | ≥98.5 | ≤0.15 | ≤0.15 | ≤14 | 6.5±1.0 | ≥2 | / | ||||||||

| F1000 | ≥97 | ≤0.15 | ≤0.15 | ≤10 | 4.5±0.8 | ≥1 | / | ||||||||

| F1200 | ≥96.5 | ≤0.15 | ≤0.15 | ≤7 | 3.0±0.5 | ≥0.8 | / | ||||||||

Features

Anvendelse

Materials for precision finishing grinding wheels (magnetic heads, etc.) and high-grade polishing grinding wheels.

Cutting and precision lapping materials for ceramics, cemented carbide, new material, osv.

Cutting and precision lapping materials for quartz, silicon and various glass and magnetic materials

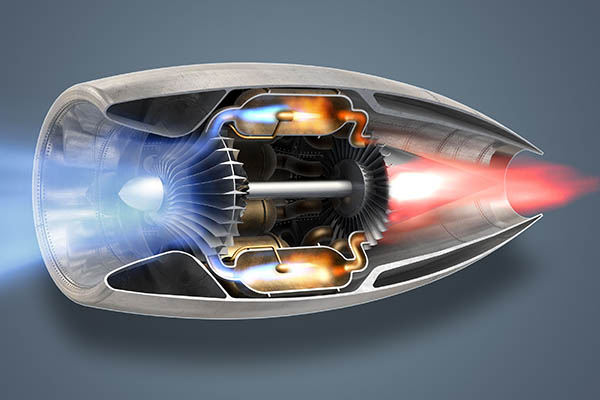

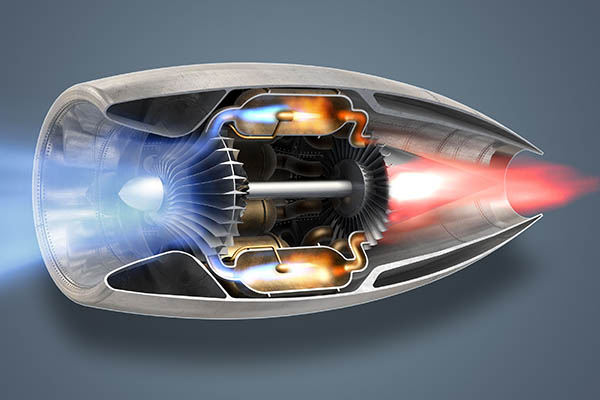

For wear-resistant, fire-resistant and corrosion-resistant materials, it can also be used to make rocket nozzles, gas turbine blades, osv.

Emballage

We can offer 1MT/25Kg Woven plastic bags, and 25Kg Paper bags.

Our Green Silicon Carbide is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Sort siliciumcarbid

Sort siliciumcarbid er et meget brugt slibende produkt, Med fremragende slidstyrke, høj hårdhed, høj densitet, lave urenheder og andre fordele, Almindeligt anvendt til slibning af sandblibning, polering, Gratis slibning, gør forskellige slibemidler, osv.

Grønt siliciumcarbid

Grønt siliciumcarbid er lavet af kvartssand og petroleumskoks raffineret i en modstandsovn, På grund af dets relativt stabile kemiske egenskaber, høj termisk ledningsevne, Lav koefficient for termisk ekspansion, og god slidstyrke.

Kontakt os

Få et tilbud

E -mail -adresse

sales@superior-abrasives.com

+86-18638638803

Adresse

No.68 Zhengtong Road, Zhengzhou, Henan, Kina