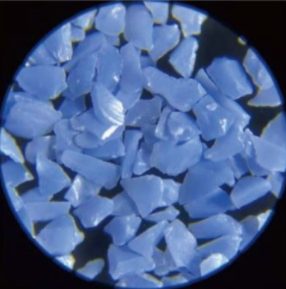

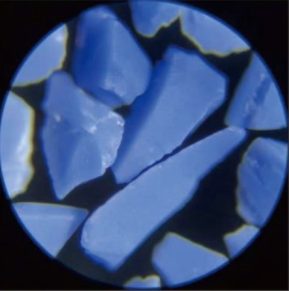

Blue Ceramic Alumina - SG slipemidler

SG Abrasives is a cutting-edge abrasive material that revolutionizes the grinding and polishing industry. Known for its exceptional durability and superior performance, SG Abrasives is a top choice for various industrial applications.

- Fast cutting speed

- Lang levetid

- Fast cold cutting, no burns

Introduction

![]()

![]()

Physical Properties

| Color | Blue | |||

| Vickers Hardness | 1920-2100 | |||

| True density | 3.90g/cm3 | |||

| Crystal size | 100nm~500nm | |||

| Grit Number | F16~F220 , P24~P220 | |||

| Sepcial Grit number | TB24+~TB220+ | |||

| High LDP grit | HF16~HF240, HP24~HP240 | |||

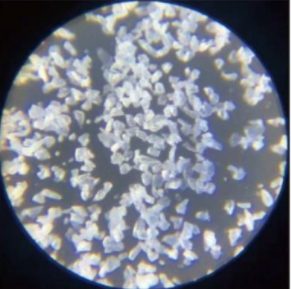

| Mikropulver | JIS #240~#10000 | |||

| F230~F2000 | ||||

| P240~P3000 | ||||

Loose Pack Density(LDP)Limits:(Macro Sizes)

| Grit | Bulk tetthet (g/cm3) | High LDP | |||

| TB | P | F | HF | HP | |

| 16# | – | – | 1.85-1.97 | >1.97 | – |

| 20# | – | – | 1.85-1.97 | >1.97 | – |

| 24# | 1.75-1.85 | 1.80-1.92 | 1.83-1.95 | >1.95 | >1.92 |

| 30# | 1.75-1.85 | 1.79-1.90 | 1.80-1.92 | >1.92 | >1.90 |

| 36# | 1.75-1.85 | 1.78-1.88 | 1.79-1.91 | >1.91 | >1.88 |

| 40# | 1.72-1.82 | 1.76-1.86 | – | – | >1.86 |

| 46# | – | – | 1.77-1.89 | >1.89 | – |

| 50# | 1.70-1.80 | 1.75-1.85 | – | – | >1.85 |

| 54# | – | – | 1.73-1.85 | >1.85 | – |

| 60# | 1.68-1.78 | 1.71-1.82 | 1.71-1.83 | >1.83 | >1.82 |

| 70# | – | – | 1.67-1.79 | >1.79 | – |

| 80# | 1.66-1.76 | 1.68-1.80 | 1.68-1.80 | >1.80 | >1.80 |

| 90# | – | – | 1.67-1.79 | >1.79 | – |

| 100# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 120# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 150# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 180# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 220# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

Applikasjoner

| P | Ideal for coated abrasives. |

| F | Ideal for bonded abrasives. Resin bonded grinding wheel and Vitrified bonded grinding wheel. |

| TB | Ideal for coated abrasives,Lower LDP than P grit larger grain size than P grit. |

| Used with conventional abrasives of the same grit number,Conventional abrasives are used as supporting parts at the bottom of coated abrasives. | |

| Ceramic abrasives grains is the main grinding force,on the top layer. | |

| HF | LDP higher than normal F grit, With higher toughness. It has the highest toughness of the ceramic abrasives. |

| Used with diamond abrasive, in resin grinding wheel, improve sharpness and life. | |

| HP | LDP higher than normal P grit. Ideal for heavy duty coated abrasives. |

| RF | Surface treated F grit. Ideal for cut-off discs and abrasive discs. |

| M | Micro powder particle size range: Japanese standard JIS240 – JIS8000; National standard F230~F1500;200/230~W3.5. |

| TG | High material removal-rate applications. |

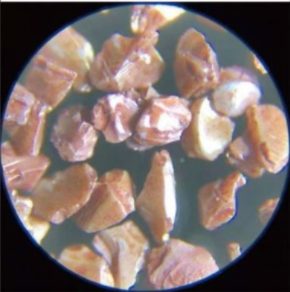

Svart silisiumkarbid

Svart silisiumkarbid er et mye brukt slipende produkt, med utmerket slitasje motstand, høy hardhet, høy tetthet, lave urenheter og andre fordeler, ofte brukt i sandblåsende sliping, polere, gratis sliping, lage forskjellige slipemidler, osv.

Grønt silisiumkarbid

Grønt silisiumkarbid er laget av kvartssand og petroleumskoks foredlet i en motstandsovn, På grunn av sine relativt stabile kjemiske egenskaper, Høy varmeledningsevne, Lav termisk ekspansjonskoeffisient, og god slitasje motstand.

Kontakt oss

Få et tilbud

E -postadresse

sales@superior-abrasives.com

+86-18638638803

Adresse

No.68 Zhengtong Road, Zhengzhou, Henan, Kina