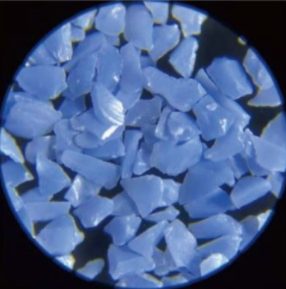

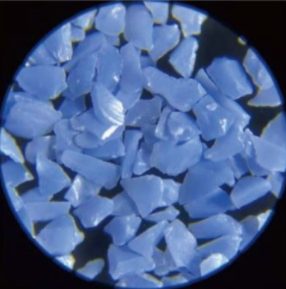

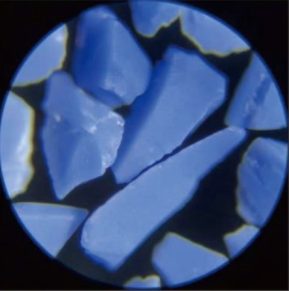

Blue Ceramic Alumina - SG abrasive

SG Abrasives is a cutting-edge abrasive material that revolutionizes the grinding and polishing industry. Known for its exceptional durability and superior performance, SG Abrasives is a top choice for various industrial applications.

- Fast cutting speed

- Long life

- Fast cold cutting, no burns

Introduction

![]()

![]()

Physical Properties

| Color | Blue | |||

| Vickers Hardness | 1920-2100 | |||

| True density | 3.90g/cm3 | |||

| Crystal size | 100nm~500nm | |||

| Grit Number | F16~F220 , P24~P220 | |||

| Sepcial Grit number | TB24+~TB220+ | |||

| High LDP grit | HF16~HF240, HP24~HP240 | |||

| Micro Powder | JIS #240~#10000 | |||

| F230~F2000 | ||||

| P240~P3000 | ||||

Loose Pack Density(LDP)Limits:(Macro Sizes)

| Grit | Kepadatan massal (g/cm3) | High LDP | |||

| TB | P | F | HF | HP | |

| 16# | – | – | 1.85-1.97 | >1.97 | – |

| 20# | – | – | 1.85-1.97 | >1.97 | – |

| 24# | 1.75-1.85 | 1.80-1.92 | 1.83-1.95 | >1.95 | >1.92 |

| 30# | 1.75-1.85 | 1.79-1.90 | 1.80-1.92 | >1.92 | >1.90 |

| 36# | 1.75-1.85 | 1.78-1.88 | 1.79-1.91 | >1.91 | >1.88 |

| 40# | 1.72-1.82 | 1.76-1.86 | – | – | >1.86 |

| 46# | – | – | 1.77-1.89 | >1.89 | – |

| 50# | 1.70-1.80 | 1.75-1.85 | – | – | >1.85 |

| 54# | – | – | 1.73-1.85 | >1.85 | – |

| 60# | 1.68-1.78 | 1.71-1.82 | 1.71-1.83 | >1.83 | >1.82 |

| 70# | – | – | 1.67-1.79 | >1.79 | – |

| 80# | 1.66-1.76 | 1.68-1.80 | 1.68-1.80 | >1.80 | >1.80 |

| 90# | – | – | 1.67-1.79 | >1.79 | – |

| 100# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 120# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 150# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 180# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 220# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

Aplikasi

| P | Ideal for coated abrasives. |

| F | Ideal for bonded abrasives. Resin bonded grinding wheel and Vitrified bonded grinding wheel. |

| TB | Ideal for coated abrasives,Lower LDP than P grit larger grain size than P grit. |

| Used with conventional abrasives of the same grit number,Conventional abrasives are used as supporting parts at the bottom of coated abrasives. | |

| Ceramic abrasives grains is the main grinding force,on the top layer. | |

| HF | LDP higher than normal F grit, With higher toughness. It has the highest toughness of the ceramic abrasives. |

| Used with diamond abrasive, in resin grinding wheel, improve sharpness and life. | |

| HP | LDP higher than normal P grit. Ideal for heavy duty coated abrasives. |

| Federasi Rusia | Surface treated F grit. Ideal for cut-off discs and abrasive discs. |

| M | Micro powder particle size range: Japanese standard JIS240 – JIS8000; National standard F230~F1500;200/230~W3.5. |

| TG | High material removal-rate applications. |

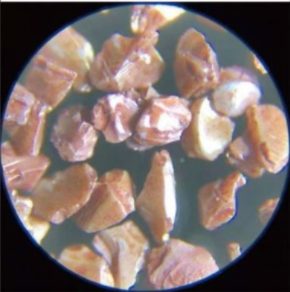

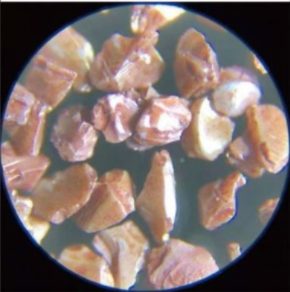

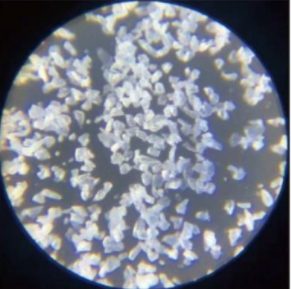

Karbida silikon hitam

Silikon karbida hitam adalah produk abrasif yang banyak digunakan, dengan ketahanan aus yang sangat baik, kekerasan tinggi, kepadatan tinggi, pengotor rendah dan keunggulan lainnya, umum digunakan dalam penggilingan sandblasting, pemolesan, penggilingan gratis, membuat berbagai bahan abrasif, dll..

Hijau silikon karbida

Silikon karbida hijau terbuat dari pasir kuarsa dan kokas minyak bumi yang dimurnikan dalam tungku tahan, karena sifat kimianya yang relatif stabil, konduktivitas termal yang tinggi, koefisien muai panas yang rendah, dan ketahanan aus yang baik.

Hubungi kami

Dapatkan Penawaran

Alamat Surel

Sales@superior-abrasives.com

+86-18638638803

Alamat

No.68 Zhengtong Road, Zhengzhou, Henan, Cina