Karbida silikon hitam

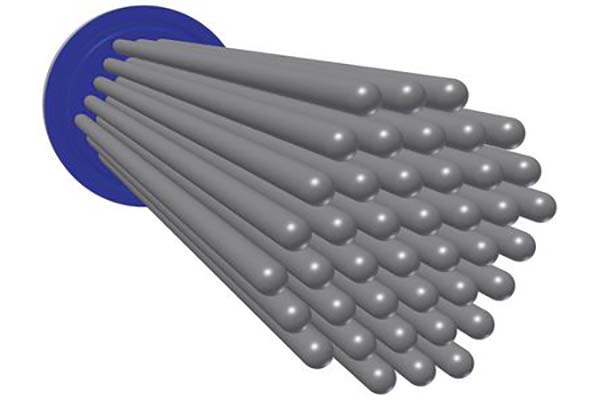

Black Silicon Carbide is the product of silicon quartz sand and petroleum coke electrofused at high temperature in an electrical resistance furnace. The grains of Black Silicon Carbide are hexagonal crystals that are extremely hard, tajam, and friable, and have outstanding electrical and thermal conductivity and low thermal expansion.

Introduction

Black Silicon Carbide is the product of silicon quartz sand and petroleum coke electrofused at high temperature in an electrical resistance furnace. The grains of Black Silicon Carbide are hexagonal crystals that are extremely hard, tajam, and friable, and have outstanding electrical and thermal conductivity and low thermal expansion.

Parameter

| Item | F Grit | Chemical Composition (%) | Size Distribution (%) | Bulk Density (g/cm3) | |||||||||||||

| Sic (% min) | Fe2O3 (% max) | F.C. (% max) | D3 | D50 | D94 | ||||||||||||

| Marco Grits | F24 | 98.50% | 0.20% | 0.20% | / | / | / | 1.43-1.53 | |||||||||

| F30 | 98.50% | 0.20% | 0.20% | / | / | / | 1.44-1.54 | ||||||||||

| F36 | 98.50% | 0.20% | 0.20% | / | / | / | 1.46-1.56 | ||||||||||

| F40 | 98.50% | 0.20% | 0.20% | / | / | / | 1.46-1.56 | ||||||||||

| F46 | 98.50% | 0.20% | 0.20% | / | / | / | 1.49-1.59 | ||||||||||

| F54 | 98.50% | 0.20% | 0.20% | / | / | / | 1.49-1.59 | ||||||||||

| F60 | 98.50% | 0.20% | 0.20% | / | / | / | 1.49-1.59 | ||||||||||

| F70 | 98.50% | 0.20% | 0.20% | / | / | / | 1.47-1.57 | ||||||||||

| F80 | 98.50% | 0.20% | 0.20% | / | / | / | 1.46-1.56 | ||||||||||

| F90 | 98.50% | 0.20% | 0.20% | / | / | / | 1.41-1.51 | ||||||||||

| F100 | 98.50% | 0.20% | 0.20% | / | / | / | 1.48-1.58 | ||||||||||

| F120 | 98.50% | 0.20% | 0.20% | / | / | / | 1.48-1.58 | ||||||||||

| F150 | 98.00% | 0.25% | 0.25% | / | / | / | 1.37-1.47 | ||||||||||

| F180 | 98.00% | 0.25% | 0.25% | / | / | / | 1.34-1.44 | ||||||||||

| F220 | 98.00% | 0.25% | 0.25% | / | / | / | 1.29-1.39 | ||||||||||

| Micro Powder | F240 | ≥99 | ≤0.15 | ≤0.15 | ≤70 | 44.5±2.0 | ≥34 | 1.36-1.5 | |||||||||

| F280 | ≥99 | ≤0.15 | ≤0.15 | ≤59 | 36.5±1.5 | ≥28 | 1.23-1.4 | ||||||||||

| F320 | ≥99 | ≤0.15 | ≤0.15 | ≤49 | 29.2±1.5 | ≥22 | 1.3-1.4 | ||||||||||

| F360 | ≥99 | ≤0.15 | ≤0.15 | ≤40 | 22.8±1.5 | ≥12 | 1.12-1.35 | ||||||||||

| F400 | ≥99 | ≤0.15 | ≤0.15 | ≤32 | 17.3±1.0 | ≥8 | 1.01-1.21 | ||||||||||

| F500 | ≥98.5 | ≤0.15 | ≤0.15 | ≤25 | 12.8±1.0 | ≥5 | 1.0-1.2 | ||||||||||

| F600 | ≥98.5 | ≤0.15 | ≤0.15 | ≤19 | 9.3±1.0 | ≥3 | 0.9-1.18 | ||||||||||

| F800 | ≥98.5 | ≤0.15 | ≤0.15 | ≤14 | 6.5±1.0 | ≥2 | 0.7-1.0 | ||||||||||

| F1000 | ≥98 | ≤0.20 | ≤0.20 | ≤10 | 4.5±0.8 | ≥1 | 0.6-0.7 | ||||||||||

| F1200 | ≥97.5 | ≤0.25 | ≤0.25 | ≤7 | 3.0±0.5 | ≥1 | 0.5-0.68 | ||||||||||

HSA silicon carbide complies with GB∕T 2480-2022 General Abrasive Silicon Carbide national standard

| Item | P Grit | Sic (% min) | Fe2O3 (% max) | F.C. (% max) | ||||||||

| Marco Grits | P16-80 | 99.00% | 0.15% | 0.15% | ||||||||

| P100 | 99.00% | 0.15% | 0.15% | |||||||||

| P120-150 | 98.50% | 0.20% | 0.20% | |||||||||

| P180-220 | 98.50% | 0.20% | 0.20% | |||||||||

| Micro Powder | P240-280 | 98.50% | 0.20% | 0.20% | ||||||||

| P320-360 | 98.50% | 0.20% | 0.20% | |||||||||

| P400-500 | 98.50% | 0.20% | 0.20% | |||||||||

| P600-800 | 98.50% | 0.20% | 0.20% | |||||||||

| P1000-1200 | 98.00% | 0.25% | 0.25% | |||||||||

| P1500-2000 | 98.00% | 0.25% | 0.25% | |||||||||

| P2500-3000-4000 | 97.50% | 0.30% | 0.30% | |||||||||

| P5000 | 97.50% | 0.30% | 0.30% | |||||||||

HSA silicon carbide complies with GB∕T 2480-2022 General Abrasive Silicon Carbide national standard

Benefits

Kekerasan Tinggi

Chemical Inertness

Kasar

Abrasion Resistance

Konduktivitas Termal Tinggi

Low Coefficient of Thermal Expansion

Thermal Shock Resistance

Strength at High-Temperature Ranges

Kemasan

We can offer 1MT/25Kg Woven plastic bags, and 25Kg Paper bags.

Our Black Silicon Carbide is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Karbida silikon hitam

Silikon karbida hitam adalah produk abrasif yang banyak digunakan, dengan ketahanan aus yang sangat baik, kekerasan tinggi, kepadatan tinggi, pengotor rendah dan keunggulan lainnya, umum digunakan dalam penggilingan sandblasting, pemolesan, penggilingan gratis, membuat berbagai bahan abrasif, dll..

Hijau silikon karbida

Silikon karbida hijau terbuat dari pasir kuarsa dan kokas minyak bumi yang dimurnikan dalam tungku tahan, karena sifat kimianya yang relatif stabil, konduktivitas termal yang tinggi, koefisien muai panas yang rendah, dan ketahanan aus yang baik.

Hubungi kami

Dapatkan Penawaran

Alamat Surel

Sales@superior-abrasives.com

+86-18638638803

Alamat

No.68 Zhengtong Road, Zhengzhou, Henan, Cina