Чорний кремній карбід мікро порошку

Домашній > Чорний карбід кремнію > Чорний кремній карбід мікро порошку

Чорний кремній карбід мікро порошку

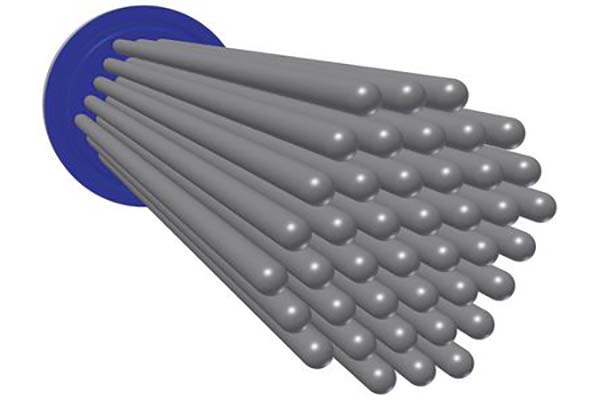

Black Silicon Carbide Micro Powder refers to the silicon carbide raw block after crushing and grinding by Raymond machine, airflow mill, ball mill and shaping machine to form a silicon carbide product of 100UM to fine, and then graded into different standard micronized products by overflow method.

Вступ

Black silicon carbide micro powder refers to the silicon carbide raw block after crushing and grinding by Raymond machine, airflow mill, ball mill and shaping machine to form a silicon carbide product of 100UM to fine, and then graded into different standard micronized products by overflow method. The production method of black silicon carbide micro powder mainly adopts dry, wet and combined wet and dry methods to meet the needs of different fields.

Black silicon carbide micro powder products are mainly used in a wide range of fields such as coated abrasives, cemented abrasives, refractory products manufacturing, foam ceramic industry, ceramic reaction sintering, solar wafer cutting, crystal cutting and grinding, automobile engine original parts manufacturing, special coating industry, rubber and plastic products modification, desulfurization, power supply, environmental protection industry, тощо.

Параметр

| Піщинка | Хімічний склад (%) | Розподіл за розміром (%) | Насипна щільність | ||||||||||||

| SIC | Fe2O3 | F.C. | D3 | D50 | D94 | ||||||||||

| F240 | ≥99 | ≤0,15 | ≤0,15 | ≤70 | 44.5±2,0 | ≥34 | 1.36-1.5 | ||||||||

| F280 | ≥99 | ≤0,15 | ≤0,15 | ≤59 | 36.5±1,5 | ≥28 | 1.23-1.4 | ||||||||

| F320 | ≥99 | ≤0,15 | ≤0,15 | ≤49 | 29.2±1,5 | ≥22 | 1.3-1.4 | ||||||||

| F360 | ≥99 | ≤0,15 | ≤0,15 | ≤40 | 22.8±1,5 | ≥12 | 1.12-1.35 | ||||||||

| F400 | ≥99 | ≤0,15 | ≤0,15 | ≤32 | 17.3±1,0 | ≥8 | 1.01-1.21 | ||||||||

| F500 | ≥98,5 | ≤0,15 | ≤0,15 | ≤25 | 12.8±1,0 | ≥5 | 1.0-1.2 | ||||||||

| F600 | ≥98,5 | ≤0,15 | ≤0,15 | ≤19 | 9.3±1,0 | ≥3 | 0.9-1.18 | ||||||||

| F800 | ≥98,5 | ≤0,15 | ≤0,15 | ≤14 | 6.5±1,0 | ≥2 | 0.7-1.0 | ||||||||

| F1000 | ≥98 | ≤0.20 | ≤0.20 | ≤10 | 4.5±0,8 | ≥1 | 0.6-0.7 | ||||||||

| F1200 | ≥97.5 | ≤0.25 | ≤0.25 | ≤7 | 3.0±0,5 | ≥1 | 0.5-0.68 | ||||||||

Benifits

Висока твердість

Хімічна інертність

Абразивний

Стійкість до стирання

Висока теплопровідність

Низький коефіцієнт теплового розширення

Стійкість до термічного удару

Міцність у діапазонах високих температур

Упаковка

Ми можемо запропонувати 1 млн/25 кг тканих пластикових пакетів, і 25 кг паперових пакетів.

Our Black Silicon Carbide is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Чорний карбід кремнію

Чорний карбід кремнію є широко використовуваним абразивним продуктом, з відмінною зносостійкістю, висока твердість, висока щільність, низький вміст домішок та інші переваги, зазвичай використовується для піскоструминного шліфування, полірування, вільний помел, виготовлення різних абразивів, тощо.

Зелений карбід кремнію

Зелений карбід кремнію виготовляється з кварцового піску та нафтового коксу, очищеного в печі опору, через його відносно стабільні хімічні властивості, висока теплопровідність, Низький коефіцієнт теплового розширення, і хороша зносостійкість.

Зв’яжіться з нами

Отримайте цитату

Електронна адреса

sales@superior-abrasives.com

+86-18638638803

Адреса

№68 Zhengtong Road, Чженчжоу, Хенан, Китай